– Battery cell containers produced by the leading European manufacturer are made of SAN plastic resistant to high and low temperature

– Lids with dependable poles seals to prevent the decrease of electrolyte

– The basis for batteries are made of steel and covered by polyethylene coating applied by fluidization. The coating is resistant to shock, acid and any weather condition,

– The highest quality flexible connectors and screws connecting cells in the battery are fully insulated and provide full protection against short circuits.Construction of OPzS batteries

– Lids with dependable poles seals to prevent the decrease of electrolyte

– The basis for batteries are made of steel and covered by polyethylene coating applied by fluidization. The coating is resistant to shock, acid and any weather condition,

– The highest quality flexible connectors and screws connecting cells in the battery are fully insulated and provide full protection against short circuits.Construction of OPzS batteries

- Positive plates

The grid of the tubular positive plate consists of several lead spines which are joined together by the upper frame. The plate is made of low-antimony alloy 1,7% with the addition of substances preventing the creation of crystalline structures. The core is die cast. This provides homogeneity of lead alloy in the whole core. Positive plate is tubular, which means that the condensed active mass (PbO2) is placed in special tubes (gauntlets) cured by impregnation and sealed from the bottom with a plug from polyester fibers. This construction provides excellent penetration of electrolyte through the walls of tubes, while preventing the active mass from dropping to the bottom of the container. The tubes are filled on wet which ensures homogeneity and repeatability of cells measurements.

- Negative plates

Negative plate is made of the technology guaranteeing high porosity active mass. Negative plate grids are die cast from low antimony lead alloy with the addition of substances preventing from the creation of crystalline structures. Plates are inserted into a special mesh of Sireg production to prevent active mass from dropping.

- Container and lid

The container is made of transparent plastic and the lid of gray high-resistant plastic (type SAN – Styrene Acrylonitrile). Lid and container are being glued and are 100% ficients against the escape of gas or leakage of electrolyte. Acid-resistant rubber seals around the poles prevent electrolyte loss during transport and operation.

- Separators

High reputable manufacturer Daramic separators insulating positive plates from negative ones are made of microporous polyethylene with low electrical resistance. They are characterized by high resistance to sulfuric acid, high temperature and aging processes

- Terminals

Terminals made of corrosion-resistant alloy of lead with a brass core reducing fastness and increasing the value of maximum current

- Terminals sealing

Plastic grommet with special seal

- Connector

Fully insulated solid copper with full insulated screw with measurements hole

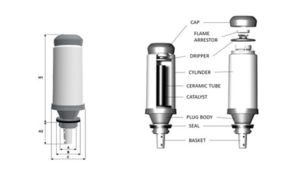

- Recombination plug

RecombinationpPlugs prevent hydrogen emission, virtually eliminating the need to refill the water and reducing the battery room ventilation requirements to the level of VRLA batteries